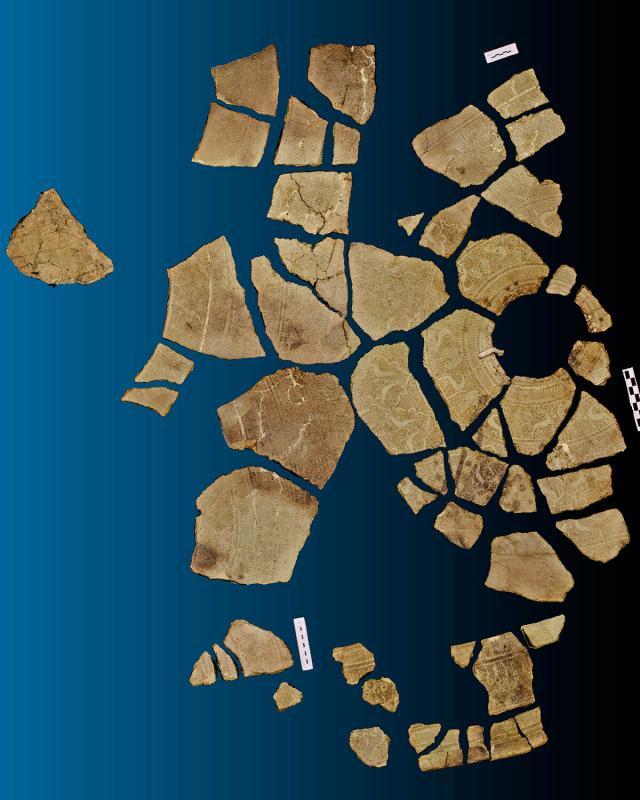

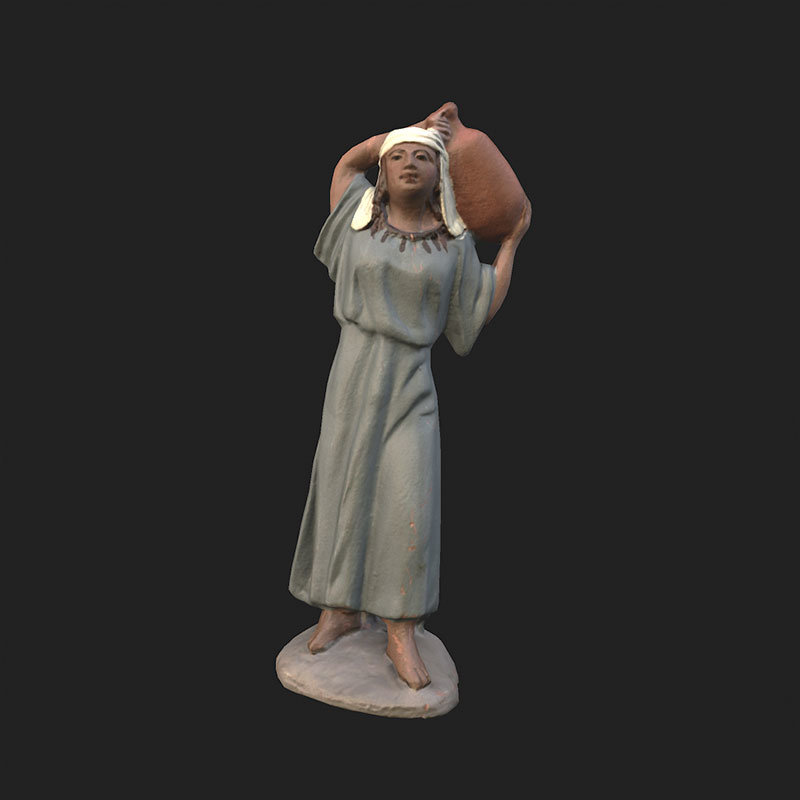

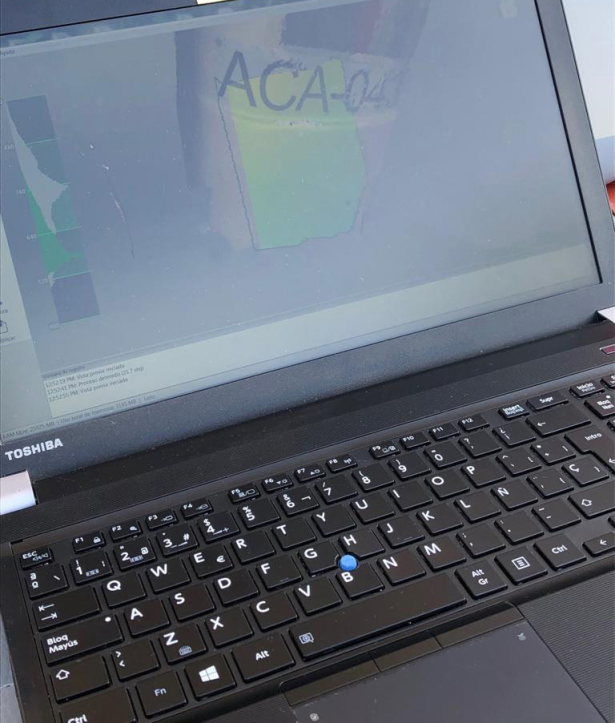

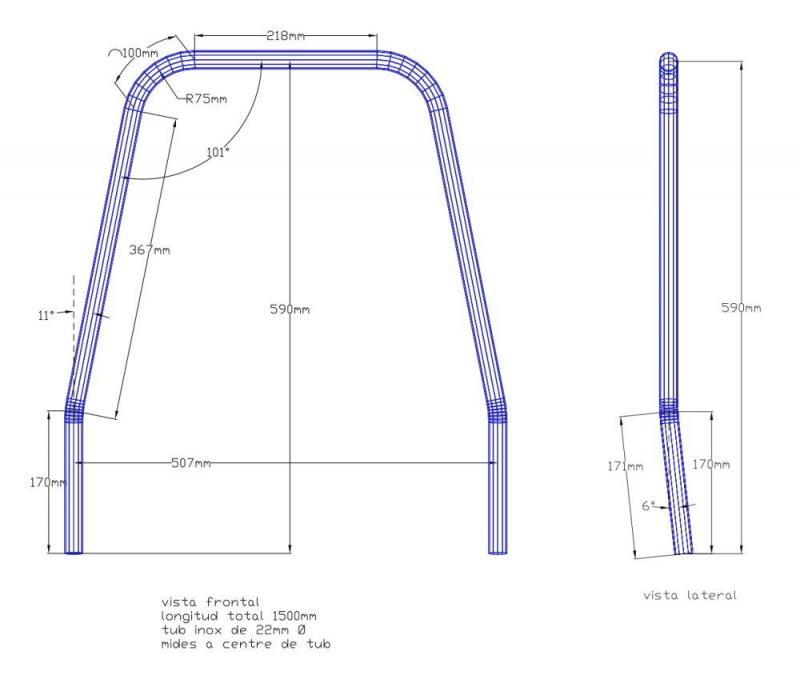

Replica of an object, through 3D scanning and printing.

Have you created an object with your hands and would like to reproduce it?

Don’t find on the market the spare of the broken piece for your historical vehicle, boat or appliance?…

3D printing is an incredible technology that allows you to create three-dimensional physical objects from digital designs. It’s like bringing your ideas to life and creating things you can touch and feel.

Imagine you have a regular printer that can print on paper, but instead of ink, it uses special materials like plastic or metal to build a solid object layer by layer in three dimensions. Instead of printing on a single plane like a sheet of paper, the 3D printer adds layers upon layers until the object is fully formed.

To do this, you first need a digital design of the object you want to print. You can scan your favorite object in 3D, create a design using specialized 3D modeling software, or download pre-made designs from the internet. Once you have the design, you load it into the 3D printer, choose the material you want to use, and start the process.

During printing, the machine starts depositing the material layer by layer, following the digital design you provided. The final result is a solid and tangible object that you can hold in your hands.

In a generic 3D printer (e.g., FDM), you have a special carriage (extrusion head) that moves in two directions: back and forth (X-axis) and left to right (Y-axis). Then, you have a base (platform) that moves up and down (Z-axis).

Now, imagine you’re printing a 3D cube. The printer would start at the base with the first layer. Then, the carriage would move in the X and Y directions to deposit material and form a square on the base. This would be the first layer of the cube.

Once the first layer is completed, the platform moves slightly up (or down, depending on the type of 3D printing technology), allowing the printer to start working on the second layer. Again, the carriage moves in the X and Y directions to add material and form a new square. Now, we have two overlaid layers.

This process is repeated layer after layer until the cube is fully formed. The more layers the object has, the more detailed and complex it will be.

The number of polygons a 3D model needs to be printed depends on various factors such as the size and complexity of the object, as well as the type of 3D printer being used for printing. Generally, most 3D printers can print models with a resolution of up to 100 micrometers. This means the model should have enough polygons for its shape to be recognizable and sharp at this scale. As a rule of thumb, 3D models should have at least 100,000 polygons for quality 3D printing.

However, it’s also important to consider the size of the file. If the model has too many polygons, it may become too large and difficult to manipulate. In this case, it’s recommended to simplify the model by reducing the number of polygons to maintain the resolution but decrease the file size.

Most modern 3D printers work with triangles, so 3D models for printing are converted into a network of triangles. This is because triangles are easier to process for the 3D printer as they can be subdivided into smaller triangles to achieve the desired resolution.

This doesn’t mean that quads (four-sided polygons) cannot be used for creating 3D models for 3D printing. In fact, many 3D design programs allow for working with quads, and models created with quads can be converted into triangles for 3D printing. However, it’s recommended to create 3D models using triangles directly to ensure better compatibility with 3D printers.

The 3D printing speed varies depending on several factors, such as the 3D printer model, the type of material being used, the complexity of the model, the selected layer height, and other configuration settings.

In general, most 3D printers for domestic and commercial use print at a speed of 30-120 mm/s. More advanced and larger 3D printers can print at higher speeds, but this can affect the print quality, resolution, and reliability.

Printing at a higher speed can result in a faster print, but it can also generate more vibrations and inaccuracies that may affect the print quality. On the other hand, printing at a slower speed may be slower, but generally offers better quality and more accuracy.

And what about color? 3D printing in color is an increasingly accessible technology. There are several ways to produce 3D models in color, and the most common is to use a 3D printer equipped with multiple extruders that can print in different colors.

In this case, the 3D model is broken down into different files, one for each color, and the 3D printer prints each color separately on its corresponding extruder. The 3D printer moves between different regions of the model to print each color where it’s needed. This allows the creation of 3D models with different shades and textures.

There are also other technologies that allow 3D printing in color, such as ink 3D printing or light 3D printing. These methods use different techniques for color printing, such as injecting ink into layers of powder, solidifying photosensitive materials in different colors, or projecting light at different wavelengths to create different colors.

The thickness of each layer is another important aspect. It’s like the height of each level of the cube. If you choose a smaller layer thickness, for example, 0.1 mm, the layers will be thinner, and the final object will be smoother and more detailed. If you choose a larger layer thickness, like 0.3 mm, the layers will be thicker, and the final object will have fewer details, but the printing will be faster.

The choice of layer thickness is important depending on the type of object you want to print. For objects that require high precision, such as detailed figures or mechanical parts, thinner layers are used. For larger and less detailed objects, thicker layers can be used to speed up the printing process.

3D printing has many applications, from creating spare parts and prototypes for industries to making toys, jewelry, custom action figures, or even medical prosthetics. It’s also a valuable tool for education, as it allows exploring design, engineering, and creativity concepts.

There are several technologies used in 3D printing, each with its specific characteristics and applications.

Here are some of the most common ones:

Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF): This is one of the most popular and accessible technologies. It uses melted plastic filaments (such as PLA or ABS) that are extruded layer by layer to build the object.

Stereolithography (SLA): It uses an ultraviolet laser to solidify successive layers of photosensitive liquid resin, creating models with high precision and fine details.

Selective Laser Sintering (SLS): It uses a laser to fuse layers of materials like nylon, polyamide, or metal, creating durable and complex objects.

Digital Light Processing (DLP): Similar to SLA, but instead of a laser, it uses digital projectors to cure photosensitive resin in layers.

Selective Laser Melting (SLM) / Electron Beam Melting (EBM): These technologies are used for 3D metal printing. They use a laser or an electron beam to melt and fuse metal powder layer by layer.

PolyJet: It uses print heads to deposit drops of liquid material that solidify with ultraviolet light, allowing printing objects in full color and high precision.

Binder Jetting: It uses a chemical binder to bind layers of metal, ceramic, or sand, creating objects with details and textures.

Laminated Object Manufacturing (LOM): It uses layers of laminated materials, such as paper or plastic, that are cut and joined to form the object.

Material Jetting: Similar to PolyJet, but it uses print heads that deposit liquid material that solidifies with ultraviolet light or heat.

Continuous Liquid Interface Production (CLIP): A technology similar to SLA that uses a permeable oxygen “window” to solidify liquid resin instead of using layers.

It’s important to note that 3D printing technology is constantly evolving, and new technologies are emerging regularly. Each of these technologies has its advantages and disadvantages and is selected based on the specific requirements of each project.

In 3D printing, there is a wide variety of materials available, ranging from rigid to flexible and elastic, as well as others . The choice of material depends on the type of object you want to print and its specific characteristics.

Technically feasible materials:

Plastics: Plastics are the most common material for 3D printing and include PLA, ABS, PETG, Nylon, among others.

Metals: 3D printing of metals such as aluminium, stainless steel, titanium or copper is becoming an increasingly popular option.

Resins: Photopolymeric resins are materials that are solidified by UV light. These resins can be used to create detailed and high resolution objects.

Wood: Can be printed with real wood, recycled wood and wood-like materials, which offer a look and texture similar to this material.

Food: Yes, 3D printing is also used to create food, such as chocolate, pasta or even pizzas.

Other materials: Other materials that can be used for 3D printing include paper, rubber, concrete and wax.

Rigid materials (plastics and resins):

PLA (polylactic acid): One of the most common and easy-to-use materials. It is biodegradable, non-toxic, and offers good strength and rigidity.

ABS (acrylonitrile butadiene styrene): A durable and strong material suitable for applications requiring higher impact resistance and higher temperatures than PLA.

Nylon: Offers high strength and durability, with a slightly flexible surface. It is used in applications that require resistant mechanical parts.

Flexible and elastic materials:

TPU (thermoplastic polyurethane): An elastic and flexible material, ideal for printing objects that need some flexibility and wear resistance, such as phone cases or shoe soles.

TPE (thermoplastic elastomer): Similar to TPU, it is an elastic and flexible material used for printing objects with rubber-like properties, such as gaskets or seals.

In addition to these, there are also specialized materials, such as flexible resins in SLA or SLS printers, which allow a greater variety of properties and applications.

If you are 3D printing the model yourself, it is important to verify the material compatibility with your 3D printer, as not all printers can work with all materials. Some printers may require adjustments or modifications to work with flexible materials due to their unique extrusion or curing characteristics.

In 3D printing, you can also work with a wide variety of metals, which has opened up many opportunities for advanced and customized manufacturing.

3D metal printing has revolutionized various industries, as it allows the production of complex parts with custom geometries that were difficult or even impossible to achieve with traditional manufacturing methods.

It’s important to consider that 3D metal printing is usually carried out using more advanced and costly technologies, such as Selective Laser Melting (SLM) or Electron Beam Melting (EBM). These processes use a laser or electron beam to melt and fuse metal powder layer by layer to obtain solid and durable objects.

Some of the most common metals used in 3D printing are:

Aluminum: A lightweight and resistant metal used in a variety of applications, from aerospace components to automobile parts.

Stainless Steel: A material widely used in 3D printing due to its strength and durability. It is used in applications that require high corrosion resistance and high temperatures.

Titanium: A very lightweight and strong metal used in aerospace, medical, and industrial applications.

Nickel: Used in applications requiring resistance to high temperatures and corrosion, such as in the aerospace and energy industries.

Cobalt-Chromium: A material used in medical applications, such as for implants and prosthetics, due to its biocompatibility.

Alloys of aluminum, titanium, or nickel: There are various alloys of these metals used to print parts with specific properties.

Bronze: Used to create decorative objects or parts with fine details.

Copper: Used in electrical and electronic applications, as well as in jewelry.

Gold and Silver: Used in the jewelry industry and specialized applications.