Reconstruction with 3D scanner of discontinued spare part.

A project to regenerate a discontinued spare, with a combination of scanned and 3D printing, and with the possibility of modifying what you want.

This boat, a semi-rigid inflatable of 4.5m in length and several years above, did not have methacrylate windshield or stainless steel tube protection around it. The owner of the boat tried to get it without success, it was already discontinued and it was impossible to find it, new or used.

He contacted Scan3DCat to find a solution with our 3D scanning service. And we started to develop it, with his collaboration.

The project would consist of scanning the console on the boat to have the exact shape and measurements. In our study we model the necessary parts (screen and stainless steel tube) with 3D editing software, and with a very high precision (0.1mm).

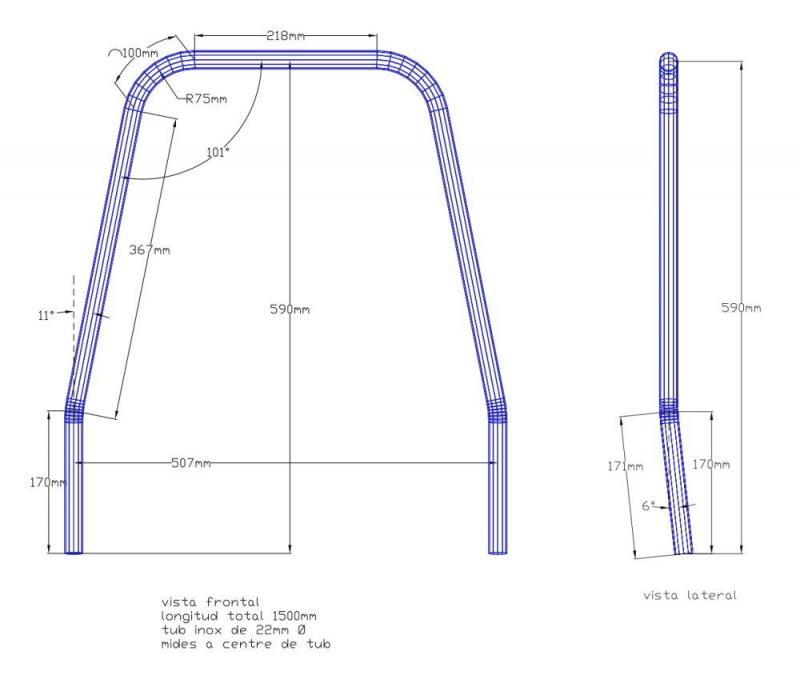

The stainless tube was drawn in 3D, dimensioned CAD drawings were drawn and a company specialized in tube bending was asked to prepare it with a 22mm diameter stainless steel tube (AISI 316) (one of the standard nautical measurements for railings and handrails), according to the specified measures.

Subsequently, we modeled a “mold” of the screen in negative (the inside) to 3D print with ABS resins (acrylonitrile butadiene styrene), to be able to couple on top of this mold, heating with hot air a 3mm thick methacrylate plate with the flat shape, already laser cutted. ABS printing material withstands more stress and more temperature than PLA (polylactic acid), which is the most common in 3D printing.

There was the possibility of printing it on other more resistant materials, such as metallic ones, but this time it was enough ABS resin.

The mold material should be resistant, at least, at a temperature of 120 ° C. The methacrylate loses its stiffness from 100-110ºC and it was intended to bend it with hot air at this temperature above the mold. ABS would resist it.

Working on the 3D model of the console with 3D editing software, we extracted the flat 2D (extended) form of the future screen, in CAD format.

A new plate of 1000x600x3mm of tobacco colored methacrylate was passed through the laser cut, introducing into the cutting machine the previous CAD file. The finish of the cut edges is perfect.

Once the methacrylate shape was cut, this as a template was used to draw and cut the same shape on a thick paper (more than 200gr / m2 or cardboard) so that the roughness of the mold does not influence when heating and molding the methacrylate . This roughness is due to a 3D printing of the mold with less resolution to speed up the printing time and, therefore, costs.

The molding was a success. Only just had to attach and screw in the usual way, with stainless steel screws and washers.

Subsequently, the designed stainless steel protection/clamping tube is also attached to the console, with the appropriate supports (AISI 316) purchased in specialized stores.

At Scan3DCat we have the digital files used in this project for this particular console model, both 3D meshes and 2D and CAD drawings. If any company/individual is interested in them, we are at your disposal.

We can also start a new project with any other console model.